Types:

Casing Pipe, Oil Well Casing, OCTG Casing & Tubing

Grades of Casing:

API 5CT J55/K55/N80/L80-1/L80-9Cr/L80-13Cr/P110/Q125/K55 D10/L80 D10

Sizes of Casing:

Sizes of Casing:

Diameter: from 4 1/2 inch to 20 inch (48.26mm - 508mm)

Nominal Weight: from 9.5 lb/ft to 169 lb/ft

from 9.5 ppf to 169 ppf

Lenght: R1, R2, R3

Types of Casing:

Casing nipple

Connection:

BTC, STC, LTC, NUE, EUE

Coating

|

3PP Coating |

3PE Coating |

FBE Coating |

Epoxy Coating |

Special Painting |

Applications:

Oil well extracting casing

Borehole casing

Borewell casing

Dimension Tolerance of casing pipe

|

Types of steel tubes |

Outer Diameter |

Wall Thickness |

|

|

Cold-rolled tubes |

Tube sizes(mm) |

Tolerances(mm) |

Tolerances(mm) |

|

<114.3 |

±0.79 |

-12.5% |

|

|

≥114.3 |

-0.5%,+1% |

||

Chemical Composition of casing pipe

| Standard | Grade |

Chemical compositions(%) |

|||||||||

|

API SPEC 5CT |

J55 |

C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 |

0.34~0.39 |

0.20~0.35 |

1.25~1.50 |

≤0.020 |

≤0.015 |

≤0.15 |

≤0.20 |

≤0.20 |

/ | / | |

|

N80 |

0.34~0.38 |

0.20~0.35 |

1.45~1.70 |

≤0.020 |

≤0.015 |

≤0.15 |

/ | / | / |

0.11~0.16 |

|

|

L80 |

0.15~0.22 |

≤1.00 |

0.25~1.00 |

≤0.020 |

≤0.010 |

12.0~14.0 |

≤0.20 |

≤0.20 |

/ | / | |

|

P110 |

0.26~0.395 |

0.17~0.37 |

0.40~0.70 |

≤0.020 |

≤0.010 |

0.80~1.10 |

≤0.20 |

≤0.20 |

0.15~0.25 |

≤0.08 |

|

Mechanical properties of casing pipe

| Grade | Type |

Total elongation under load (%) |

Yield strength (min) |

Yield strength (max) |

Tensile strength min Mpa |

Hardness Max (HRC) |

Hardness Max(HBW) |

| J55 | - |

0.5 |

379 | 552 | 517 | - | - |

| K55 | - |

0.5 |

379 | 552 | 655 | - | - |

| N80 | 1 |

0.5 |

552 | 758 | 689 | - | - |

| N80 | Q |

0.5 |

552 | 758 | 689 | - | - |

| L80 | 1 |

0.5 |

552 | 655 | 655 | 23 | 241 |

|

L80 |

9Cr |

0.5 |

552 | 655 | 655 | 23 | 241 |

|

L80 |

13Cr |

0.5 |

552 | 655 | 655 | 23 | 241 |

| C90 | - |

0.5 |

621 | 724 | 689 | 25.4 | 255 |

| C95 | - |

0.5 |

655 | 758 | 724 | - | - |

| T95 | - | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | - | 0.6 | 758 | 965 | 862 | - | - |

| Q125 | All | 0.65 | 862 | 1034 | 931 | - | - |

Casing Pipe is used to support the oil, gas wells of steel pipe, in order to ensure the drilling process and the completion of the entire well after the normal operation. Each well has several layers of casing depending on the drilling depth and geology. Casing down to use cement cementing, it and the tubing, drill pipe is different, can not be reused, a one-time consumption of materials. Therefore, the casing of the total consumption of more than 70% of the wells. Casing according to the use can be divided into: catheter, surface casing, casing technology and oil casing.

Tubing Pipe is the conduit through which oil and gas are brought from the producing formations to the field surface facilities for processing. Tubing must be adequately strong to resist loads and deformations associated with production and workovers. Further, tubing must be sized to support the expected rates of production of oil and gas. Clearly, tubing that is too small restricts production and subsequent economic performance of the well. Tubing that is too large, however, may have an economic impact beyond the cost of the tubing string itself, because the tubing size will influence the overall casing design of the well.

API Tubing Pipe Size: API Tubing naturally has a smaller diameter than casing, except for the 4 1/2-inch diameter. An outer diameter of 114.3 mm (4 1/2 inches) is considered a threshold and can be either casing or tubing. Anything smaller is called tubing, anything larger is casing.

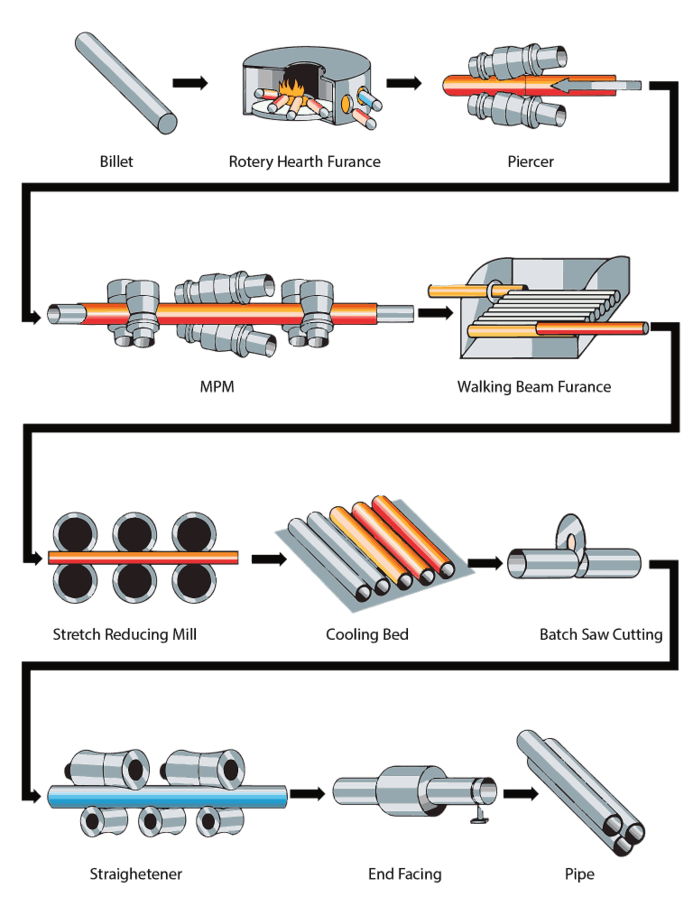

Casing Pipe Manufacturing Process:

Steel ingot heating → hydraulic punching → reheating → extension → periodic rolling → reheating → sizing → cooling → straightening → pipe cutting → inspection

1. An annular heating furnace is required for ingot heating;

2. Punching and reheating with hydraulic press;

3. The oil casing plant uses a two-roller guide plate extension machine for extension;

4. Re-use a disc heating furnace for periodic rolling, and use a non-entry furnace for reheating, cooling, straightening, pipe cutting, and inspection.

Color Codes for API 5CT Casing and Tubing:

Product picture display:

P110 Grade

N80 Grade

J55 Grade

| Casing Size | Casing Coupling | Nominal Weight | Inside Diameter |

|

OD |

OD | LB/FT | ID |

|

INCH |

INCH | PPF | INCH |

| 4 1/2" (4.500) | 5.000" | 9.50 lb/ft (ppf) | 4.090" |

|

5.000" |

10.50 lb/ft (ppf) | 4.052" | |

|

5.000" |

11.60 lb/ft (ppf) | 4.000" | |

|

5.000" |

13.50 lb/ft (ppf) | 3.920" | |

| 5" | 5.563" | 11.50 lb/ft (ppf) | 4.560" |

|

5.563" |

13.00 lb/ft (ppf) | 4.494" | |

|

5.563" |

15.00 lb/ft (ppf) | 4.408" | |

|

5.563" |

18.00 lb/ft (ppf) | 4.276" | |

| 5 1/2" (5.500) | 6.050" | 14.00 lb/ft (ppf) | 5.012" |

|

6.050" |

15.50 lb/ft (ppf) | 4.950" | |

|

6.050" |

17.00 lb/ft (ppf) | 4.892" | |

|

6.050" |

20.00 lb/ft (ppf) | 4.778" | |

|

6.050" |

23.00 lb/ft (ppf) | 4.670" | |

| 6 5/8" (6.625) | 7.390" | 20.00 lb/ft (ppf) | 6.049" |

|

7.390" |

24.00 lb/ft (ppf) | 5.921" | |

|

7.390" |

28.00 lb/ft (ppf) | 5.791" | |

|

7.390" |

32.00 lb/ft (ppf) | 5.675" | |

| 7" | 7.656" | 17.00 lb/ft (ppf) | 6.538” |

|

7.656" |

20.00 lb/ft (ppf) | 6.456" | |

|

7.656" |

23.00 lb/ft (ppf) | 6.366" | |

|

7.656" |

26.00 lb/ft (ppf) | 6.276" | |

|

7.656" |

29.00 lb/ft (ppf) | 6.184" | |

|

7.656" |

32.00 lb/ft (ppf) | 6.094" | |

|

7.656" |

35.00 lb/ft (ppf) | 6.004" | |

|

7.656" |

38.00 lb/ft (ppf) | 5.920" | |

| 7 5/8" (7.625) | 8.500“ | 20.00 lb/ft (ppf) | 7.125" |

|

8.500” |

24.00 lb/ft (ppf) | 7.025" | |

|

8.500" |

26.40 lb/ft (ppf) | 6.969" | |

|

8.500" |

29.70 lb/ft (ppf) | 6.875" | |

|

8.500" |

33.70 lb/ft (ppf) | 6.765" | |

|

8.500" |

39.00 lb/ft (ppf) | 6.625" | |

| 8 5/8" (8.625) | 9.625" | 24.00 lb/ft (ppf) | 8.097 |

|

9.625" |

28.00 lb/ft (ppf) | 8.017" | |

|

9.625" |

32.00 lb/ft (ppf) | 7.921" | |

|

9.625" |

36.00 lb/ft (ppf) | 7.825" | |

|

9.625" |

40.00 lb/ft (ppf) | 7.725" | |

|

9.625" |

44.00 lb/ft (ppf) | 7.625" | |

|

9.625" |

49.00 lb/ft (ppf) | 7.511" | |

| 9 5/8" (9.625) | 10.625" | 29.30 lb/ft (ppf) | 9.063" |

|

10.625” |

32.30 lb/ft (ppf) | 9.001" | |

|

10.625“ |

36.00 lb/ft (ppf) | 8.921" | |

|

10.625“ |

40.00 lb/ft (ppf) | 8.835“ | |

|

10.625” |

43.50 lb/ft (ppf) | 8.755” | |

|

10.625 |

47.00 lb/ft (ppf) | 9.681” | |

|

10.625 |

53.50 lb/ft (ppf) | 8.835" | |

| 10 3/4" (10.750) | 11.750 | 32.75 lb/ft (ppf) | 10.192" |

|

11.750” |

40.50 lb/ft (ppf) | 10.050“ | |

|

11.750“ |

45.50 lb/ft (ppf) |

9.950” |

|

|

11.750” |

51.00 lb/ft (ppf) | 9.850” | |

|

11.750“ |

55.50 lb/ft (ppf) | 9.760“ | |

|

11.750” |

60.70 lb/ft (ppf) | 9.660” | |

|

11.750“ |

65.70 lb/ft (ppf) | 9.560“ | |

| 11 3/4" (11.750) | 12.750” | 42.00 lb/ft (ppf) | 11.084” |

|

12.750“ |

47.00 lb/ft (ppf) | 11.000“ | |

|

12.750” |

54.00 lb/ft (ppf) | 10.880” | |

|

12.750“ |

60.00 lb/ft (ppf) | 10.772“ | |

| 13 3/8" (13.375) | 14.375" | 48.00 lb/ft (ppf) | 12.715” |

|

14.375" |

54.50 lb/ft (ppf) | 12.615“ | |

|

14.375" |

61.00 lb/ft (ppf) | 12.515” | |

|

14.375" |

68.00 lb/ft (ppf) | 12.415“ | |

|

14.375" |

72.00 lb/ft (ppf) | 12.347" | |

| 16" |

17.000" |

65.00 lb/ft (ppf) | 15.250" |

| 17.000" | 75.00 lb/ft (ppf) | 15.124" | |

|

17.000" |

84.00 lb/ft (ppf) | 15.010" | |

| 18 5/8" (13.375) | 20.000" | 87.50 lb/ft (ppf) | 17.755" |

| 20" |

21.000" |

94.00 lb/ft (ppf) | 19.124" |

|

21.000" |

106.50 lb/ft (ppf) | 19.000" | |

|

21.000" |

133.00 lb/ft (ppf) | 18.730" | |

|

21.000" |

169.00 lb/ft (ppf) | 18.376" |

|

Mexico L80 EUE 3 1/2" 9.3ppf 80,000 Meters |

Columbia J-55 (or K-55) 20",94.0 LB/FT, BTC, R3 10500 feet |

UAE K-55,N80 13-3/8", 68 ppf SMLS, BTC, R3 9-5/8", 47 ppf SMLS, BTC, R3 9560 meters |

Nigeria |

|

United States |

Zambia API GRADE L-80,SEAMLESS 7 IN.35 PPF DRIFT :5.875 IN 6000 Joints |

Nigeria AISI 4140 L80 10-3/4", 40.50PPF 30 FEET LONG 2000 Nos |

Jordan H- 40 14" O.D,45.61 Ib/ft, Range II, wt:0,312" 2700 meters

|

|

The United Arab Emirates J55, N80 Connection BTS 18-5/8", 87 ppf 13-3/8", 72 ppf 369.52 Tons |

Nigeria H-40,J55 20" CSG 94 Lb/ft, BTC with thread protectors, Range 3 13 3/8" CSG 68 Lb/ft Grade J-55, BTC, Range 3 396 Joints |

Vietnam J55, 13 3/8" #54.5 PPF, BTC, R3, 4000MTRS 9 5/8", #36PPF, BTC, R3, 2000MTRS |

Venezuela |

|

The United Arab Emirates |

Nigeria 7 "23 ppf K55 R3 BTC 67 jts 6"; thickness 5mm, length 6m : amount 126 pipes 9 5/8"; thickness 6mm; length 12m : amount 80 pipes |

Irap P110 9-7/8", 62.8ppf Vam Top Thread Range3 14000 Feet 7" 29ppf,+/-40ft,Vam Top Range 3 3000 Feet |

Oman K55 10 3/4", 40.5 PPF, 12 meters length, Qty 155 pcs 8 5/8" K55 32 PPF, 12 meters length, Qty 270 pcs

|