During the process of oil field exploitation, oil drilling casing plays a vital role. It can not only support the well wall and prevent formation collapse, but also ensure the smooth extraction of oil and gas resources. In order to meet different geological conditions and exploitation needs, various sizes of casing are used in oil fields. So, what are the commonly used specifications and dimensions of drilling casing in the process of oil drilling?

Drilling Casing Pipe Specifications:

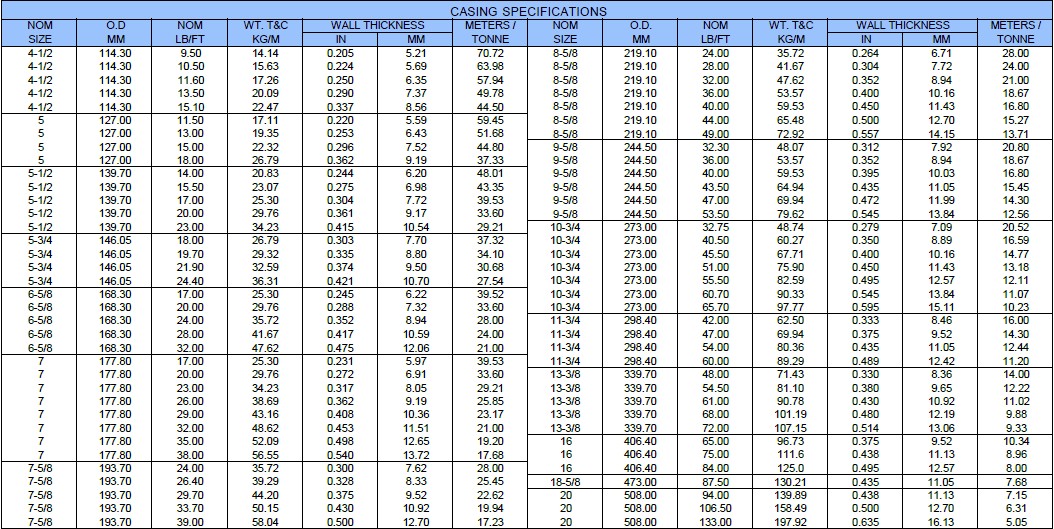

Casing pipes are ordinarily produced with outside diameter sizes of 114.3 mm to 508.0 mm. The specifications and weight of oil casing pipe are as follows:

The outer diameter of this casing is about 114.3 mm and the wall thickness is about 6.35 mm. Due to its small size, it is usually used for the exploitation of shallow oil wells. The formation pressure of shallow oil wells is relatively low, so this casing can provide sufficient support while reducing the cost of exploitation.

This type of oil casing has an outer diameter of about 244.5 mm and a wall thickness of about 14.14 mm. It is one of the largest size casings used in oil fields. It is mainly used for the mining of deep oil wells and can withstand extremely high formation pressure and temperature. At the same time, its wide inner diameter is conducive to reducing the flow resistance of oil and gas in the pipeline and improving the extraction efficiency.

The drilling steel casing used in oil fields has various specifications and sizes. The size of oil casing to be selected depends on the depth of the oil well, geological conditions and extraction requirements. The correct selection of oil casing size is crucial to ensure the safety and efficiency of oil field extraction.

Read more: Casing pipe vs. Drill pipe or Seamless Casing vs. ERW Casing

Related information