We are API 5L X42 / X46 / X52 / X60 / X65 / X70 ERW pipe experts, reliable API 5L welded pipe supplier and manufacturer in China.

API 5L ERW pipe is manufactured to American Petroleum Institute specifications. These pipelines are used to transport petroleum products and other products along long pipelines. Therefore, pipes must be strong, corrosion-resistant, and wear-resistant. Hunan Standard Steel Co., Ltd's high-frequency resistance welded (ERW) line pipe and standard electric resistance welded pipe products are smooth and thin-walled. They are produced by continuously forming coiled hot-rolled strip into tubes and welding the longitudinal seams using high-frequency resistance welding. Chemical and mechanical property requirements are specified by current API 5L and applicable ASTM standards. ERW standard line pipe is widely used throughout the oil and gas industry, as well as in pipe piling and cable duct systems.

API 5L:

API 5L is the standard for pipeline systems for the petroleum and natural gas industry, including the transportation of fluids such as petroleum, natural gas, water and oil. API 5L standards are divided into two levels, PSL1 and PSL2. The requirements of PSL1 level are relatively low, the testing requirements are not as stringent, and it is generally more cost-effective. The PSL2 level has higher technical requirements, including resistance to ductile fracture growth, sour service conditions and offshore service conditions.

ERW Standard and Line Pipe Grades:

| Grade A Carbon Steel |

(ASTM A53, A523, API 5L PSL1 ) |

|---|---|

| Minimum Yield Strength: | 30,000 psi |

| Maximum Yield Strength: | None |

| Minimum Tensile Strength: | 48,000 psi |

|

Notes: This grade may be used for standard pipe, line pipe, or conduit pipeas specified in the various ASTM and API specifications. |

|

| Grade B Carbon Steel |

(ASTM A53, A523, API 5L PSL1) |

API 5L PSL2 |

|---|---|---|

| Minimum Yield Strength: | 35,000 psi | 35,000 psi |

| Maximum Yield Strength: | None | 65,000 psi |

| Minimum Tensile Strength: | 60,000 psi | 60,000 psi |

| Maximum Tensile Strength: | None | 110,000 psi |

|

Notes: This grade may be used for standard pipe, line pipe, or conduit pipeas specified in the various ASTM and API specifications. |

||

| API 5L X42 | PSL1 | PSL2 |

|---|---|---|

| Minimum Yield Strength: | 42,000 psi | 42,000 psi |

| Maximum Yield Strength: | None | 72,000 psi |

| Minimum Tensile Strength: | 60,000 psi | 60,000 psi |

| Maximum Tensile Strength | None | 110,000 psi |

|

Notes: This is a standard line pipe grade specifiedin API (American Petroleum Institute) specification 5L. |

||

| API 5L X46 | PSL1 | PSL 2 |

|---|---|---|

| Minimum Yield Strength: | 46,000 psi | 46,000 psi |

| Maximum Yield Strength: | None | 76,000 psi |

| Minimum Tensile Strength: | 63,000 psi | 63,000 psi |

| Maximum Tensile Strength: | None | 110,000 psi |

|

Notes: This is a standard line pipe grade specifiedin API (American Petroleum Institute) specification 5L. |

||

| API 5L X52 | PSL1 | PSL2 |

|---|---|---|

| Minimum Yield Strength: | 52,000 psi | 52,000 psi |

| Maximum Yield Strength: | None | 77,000 psi |

| Minimum Tensile Strength: | 66,000 psi | 66,000 psi |

| Maximum Tensile Strength: | None | 110,000 psi |

|

Notes: This is a standard line pipe grade specifiedin API (American Petroleum Institute) specification 5L. |

||

| API 5L X56 | PSL1 | PSL2 |

|---|---|---|

| Minimum Yield Strength: | 56,000 psi | 56,000 psi |

| Maximum Yield Strength: | None | 79,000 psi |

| Minimum Tensile Strength: | 71,000 psi | 71,000 psi |

| Maximum Tensile Strength: | None | 110,000 psi |

|

Notes: This is a standard line pipe grade specifiedin API (American Petroleum Institute) specification 5L. |

||

| API 5L X60 | PSL1 | PSL2 |

|---|---|---|

| Minimum Yield Strength: | 60,000 psi | 60,000 psi |

| Maximum Yield Strength: | None | 82,000 psi |

| Minimum Tensile Strength: | 75,000 psi | 75,000 psi |

| Maximum Tensile Strength: | None | 110,000 psi |

|

Notes: This is a standard line pipe grade specifiedin API (American Petroleum Institute) specification 5L. |

||

| API 5L X65 | PSL1 | PSL2 |

|---|---|---|

| Minimum Yield Strength: | 65,000 psi | 65,000 psi |

| Maximum Yield Strength: | None | 87,000 psi |

| Minimum Tensile Strength: | 77,000 psi | 77,000 psi |

| Maximum Tensile Strength: | None | 110,000 psi |

|

Notes: This is a standard line pipe grade specifiedin API (American Petroleum Institute) specification 5L. |

||

| API 5L X70 | PSL1 | PSL2 |

|---|---|---|

| Minimum Yield Strength: | 70,000 psi | 70,000 psi |

| Maximum Yield Strength: | None | 90,000 psi |

| Minimum Tensile Strength: | 82,000 psi | 82,000 psi |

| Maximum Tensile Strength: | None | 110,000 psi |

|

Notes: This is a standard line pipe grade specifiedin API (American Petroleum Institute) specification 5L. |

||

| Grade 1 Carbon Steel | (ASTM A252) |

|---|---|

| Minimum Yield Strength: | 30,000 psi |

| Maximum Yield Strength: | None |

| Minimum Tensile Strength: | 50,000 psi |

|

Notes: This grade is a standard grade for ASTM A252. The specification coversthe requirements for welded and seamless steel piling pipe. |

|

| Grade 2 Carbon Steel | (ASTM A252) |

|---|---|

| Minimum Yield Strength: | 35,000 psi |

| Maximum Yield Strength: | None |

| Minimum Tensile Strength: | 60,000 psi |

|

Notes: This grade is a standard grade for ASTM A252. The specification coversthe requirements for welded and seamless steel piling pipe. |

|

| Grade 3 Carbon Steel | (ASTM A252) |

|---|---|

| Minimum Yield Strength: | 45,000 psi |

| Maximum Yield Strength: | None |

| Minimum Tensile Strength: | 66,000 psi |

|

Notes: This grade is a standard grade for ASTM A252. The specification coversthe requirements for welded and seamless steel piling pipe. |

|

Characteristics and advantages of Husteel Products ERW line pipe:

Some reasons why our customers prefer our carbon steel erw welded pipe products:

1. Smooth surfaces: Our hot-rolled strip steel is continuously cold formed into smooth-surface, uniform wall pipe for superior coatability and flow characteristics.

2. Stronger, lighter walls: Husteel’s higher strength, lighter gauge steel strip is fused by high frequency electric resistance welders into high toughness steel pipe that meets exacting tolerances and strength specifications.

3. Uniform dimensions and quality: Our ERW steel pipe products have uniform wall thicknesses made from hot-rolled steel strip. Husteel’s highly automated processes, combined with continuous non-destructive and visual inspection, and hydrostatic testing, means our customers are getting only the highest quality of steel pipe products.

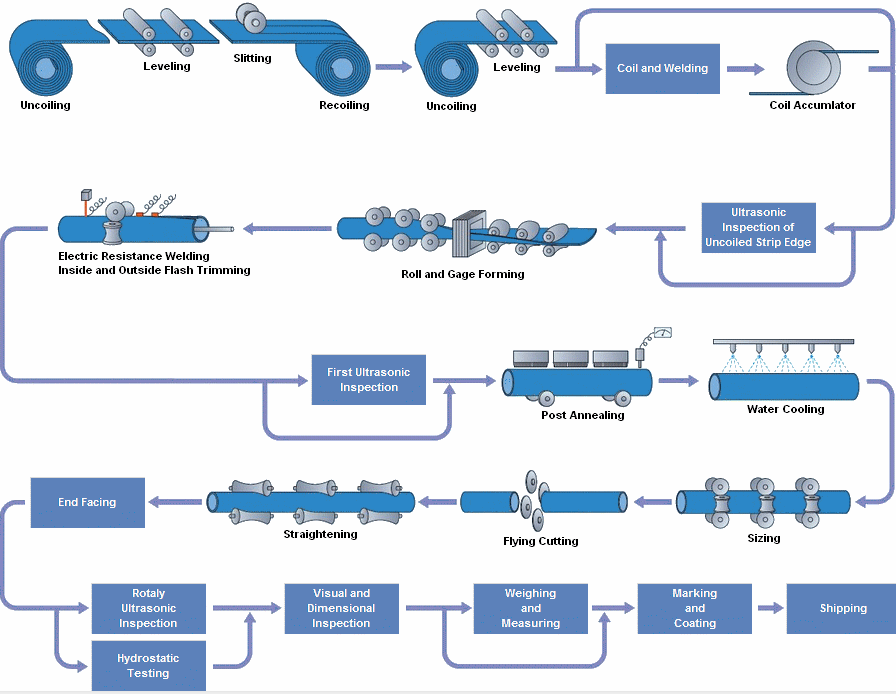

ERW line pipe manufacturing process:

Straight seam high frequency welded line pipe (ERW) is formed by forming a hot-rolled coil through a forming machine. The skin effect and proximity effect of high-frequency current are used to heat and melt the edge of the pipe blank. Pressure welding is carried out under the action of a squeeze roller. Realize production. Carbon steel ERW welded pipes have simple production process, high production efficiency, many varieties and specifications, and less equipment, but their general strength is lower than seamless steel pipes.

Read more: ERW Pipe Material Selection or ERW pipe vs Seamless pipe Cost

Related information