Cold drawn seamless tube & tubing (CDS) is used for high dimensional accuracy mechanical structure, hydraulic equipment and good surface finish cold drawn or cold rolled precision seamless steel tubes. High-precision drawing denotes the outer diameter size precision (tolerance) strict and external surface finish, roundness, straightness good thickness uniformity.

Compared with hot rolled pipe products, it features uniform tolerances, enhanced machinability, and higher strength and tolerances. Cold Drawing Process Compared with hot finishing seamless pipes, the cold drawing process improves the physical properties of the pipe and provides better tolerances and less machining allowance.

Raw material selection:

The selection of raw materials for cold drawn seamless tubes is the most basic link in the manufacturing process. Under normal circumstances, the raw materials selected should be high-quality carbon structural steel or alloy structural steel. The quality of raw materials directly affects the quality and performance of the finished pipes, so the material selection needs to be very careful.

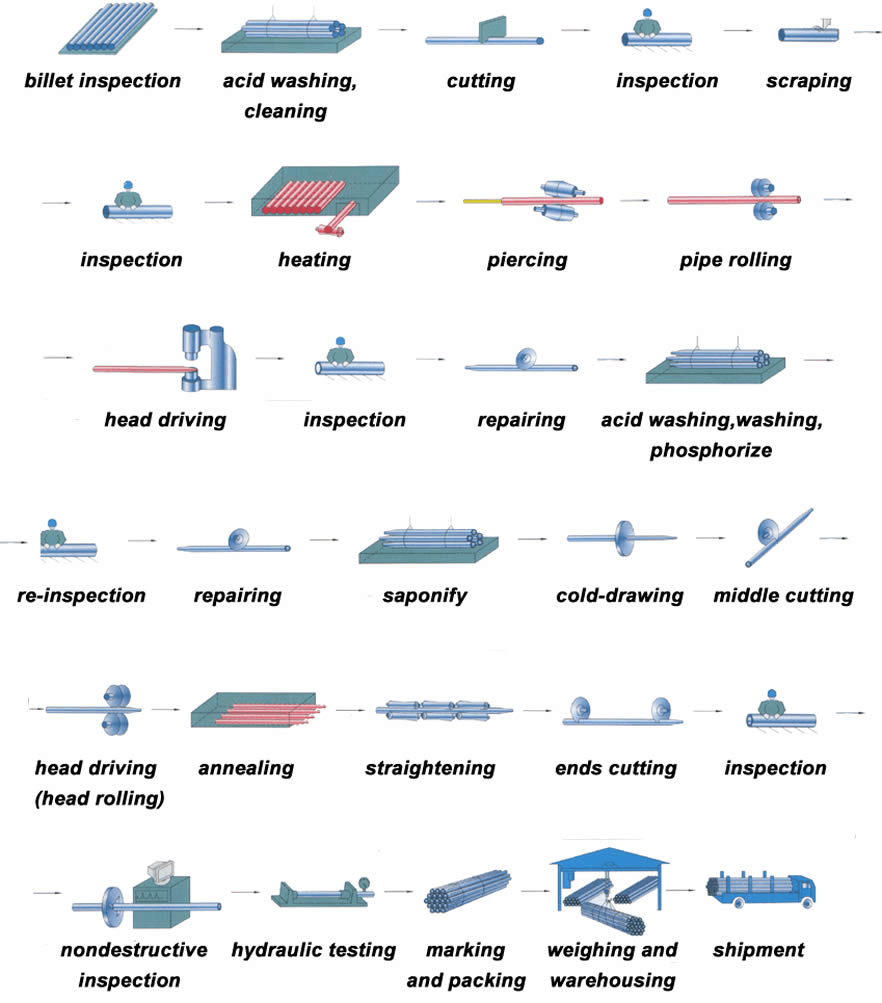

Production process of cold drawn seamless steel tubing:

1. Pickling of steel pipe blanks: pickling the raw materials to remove surface oxide scale, rust and other impurities.

2. Heating treatment: Heating the billet to a certain temperature to ensure that subsequent cold rolling processing can proceed smoothly. According to different steel types and different pipe specifications, the heating temperatures are also different.

3. Cold rolling processing: The billet is continuously rolled on a cold rolling mill. After multiple cold rollings, the raw material is continuously stretched to form a seamless steel tube with precise specifications and high quality.

4. Heat treatment: In order to eliminate the stress generated during cold working and improve the mechanical properties of seamless steel pipes, heat treatment is usually performed. The specific method is to heat the steel pipe to a certain temperature, then keep it warm for a certain period of time, and finally gradually cool it.

5. Surface treatment: Through pickling, cleaning and other processes, the oxide layer and impurities on the surface of the steel are removed and the surface finish is improved;

6. Testing and packaging: The finished steel pipes are tested for physical properties, dimensional accuracy, etc., and then packaged to facilitate storage and transportation.

Features of cold drawn seamless steel tubing:

1. Excellent surface finish: Cold drawing processing can effectively reduce the roughness and oxide layer on the surface of the steel pipe, making the surface finish higher;

2. High dimensional accuracy: Cold drawing processing can accurately control the outer diameter, wall thickness, length and other dimensional parameters of the steel tube to ensure the matching requirements of the steel pipe during use;

3. Uniform organizational structure: Cold drawing processing can improve the internal structure of steel, and uniform and fine grains are conducive to improving mechanical properties and corrosion resistance;

4. Wide scope of application: Cold-drawn seamless steel tubes can be used in machinery manufacturing, auto parts, aerospace, petrochemical and other fields to meet the needs of different fields.

Inspection and quality control of cold drawn seamless steel tubing:

In order to ensure the quality of cold drawn seamless tubes, strict inspection and quality control are required. It mainly includes the following aspects:

1. Appearance inspection: Conduct appearance quality inspection on the surface of the steel pipe. Mainly check the surface flatness, roundness, outer diameter, wall thickness, etc. of the pipe.

2. Chemical composition analysis: Analyze the chemical composition of the steel pipe to ensure compliance with relevant standards.

3. Mechanical performance testing: Test the strength, toughness and other mechanical properties of the steel pipe to determine whether the quality of the steel pipe meets the standard requirements.

4. Penetration testing: Penetration testing is performed on the internal and external surfaces of the steel pipe to detect whether there are cracks, bubbles and other defects.

Applications of cold drawn seamless steel tubing:

1. Machinery manufacturing: Cold-drawn seamless tubes are widely used in parts such as transmission shafts, gears, reducers, etc. in machinery manufacturing. They are favored for their high strength and good processability;

2. Automobile parts: Cold-drawn seamless tubes can be used in automobile chassis, exhaust systems, braking systems and other parts. They can withstand large pressure and impact forces and improve the safety performance of automobiles;

3. Aerospace: Cold-drawn seamless tubes are widely used in the aerospace field and are used to manufacture key parts such as engines and fuselage components to ensure the safety and reliability of aircraft;

4. Petrochemical industry: Cold-drawn seamless tubes can be used in transportation pipelines for oil, natural gas and other fluids. They are corrosion-resistant and high-temperature resistant, ensuring the stable operation of the pipelines.

Heat treatment of cold drawn seamless tubing:

(2) Cold drawn steel normalizing: refers to the heating of steel or steel to Ac3 or Acm (the critical temperature of steel) over 30 ~ 50 ℃, after an appropriate time to keep cool in still air in the heat treatment process . The purpose of normalizing: mainly to improve the mechanical properties of low carbon steel to improve machinability, grain refinement, elimination of tissue defects, prepare for the heat treatment, after tissue preparation.

(7) Cold drawn steel solution treatment: that the alloy is heated to a high temperature single-phase region to maintain a constant temperature, so that the excess phase fully dissolved into the solid solution after rapid cooling, in order to get over the supersaturated solid solution heat treatment process. The purpose of solution treatment: mainly to improve the ductility and toughness of steel and alloys, to prepare for the precipitation hardening treatment and so on.

The above content is a detailed introduction to the cold drawn seamless tube process. I believe readers have learned about some key links and technical indicators in the manufacturing process of cold-rolled seamless tubes. During this process, special attention needs to be paid to raw material selection and quality control to ensure the production of high-quality seamless tubes.

Read more: Carbon steel tube material or Cold drawn ERW pipe

Related information