What is Casing Pipe?

Oil Casing Pipe is a key pipe used in oil and gas drilling projects to reinforce the wellbore of oil and gas wells, isolate the formation, and protect the integrity of the wellbore. It is a core component of OCTG. It extends from the wellhead to the target formation, forming a permanent structural barrier for the wellbore, which directly affects the safety, production efficiency and life of oil and gas wells.

Each well uses several layers of casing according to different drilling depths and geological conditions. After the casing is lowered into the well, cement is used for cementing. Unlike oil pipes and drill pipes, it cannot be reused and is a disposable consumable material. Therefore, the consumption of casing accounts for more than 70% of all oil well pipes.

What is OCTG pipe?

OCTG (Oil Country Tubular Goods) is a general term for special pipes used in drilling, completion and oil production in the oil and gas industry, covering the entire process of the pipe string system from drilling to production. Its core features are high strength, corrosion resistance, and adaptability to harsh working conditions. OCTG pipelines primarily include:

Casing Pipe: Reinforces the wellbore, isolates formations, and prevents well collapse.

API Tubing: Provides a pathway for oil and gas production, transporting fluids to the surface.

Drill Pipe: Transmits weight-on-bit and torque, connecting the drill bit to surface equipment.

International Standards:

API 5CT (Casing and Tubing Specification)

API 5DP (Drill Pipe Specification)

ISO 11960 (International Equivalent Standard)

Functions of Casing Pipe:

1. Wellbore Support: Prevents wellbore collapse and maintains wellbore stability.

2. Formation Isolation: Separates formations with different pressures or fluid properties (such as water and gas layers).

3. Fluid Path: Provides a production pathway for oil and gas, preventing contamination.

4. Corrosion Protection: Reduces corrosion of the tubing string by downhole acidic media (H₂S, CO₂).

5. Completion Foundation: Provides a foundation for the installation of subsequent completion tools (such as packers and Christmas trees).

Types of Drilling Casing:

In the oil production process, casing can be categorized by usage as: Conductor, Surface Casing, Intermediate Casing, and Production Casing.

In the oil production process, casing can be categorized by usage as: Conductor, Surface Casing, Intermediate Casing, and Production Casing.

1. Conductor: Used for initial support in shallow well sections.

2. Surface Casing: Protects the wellbore from contamination by shallow water and gas formations, supports wellhead equipment, and holds the weight of other casing layers.

3. Technical Casing: Used for temporary support in complex geological conditions such as high-pressure formations and salt-gypsum formations. It separates pressures between different layers to ensure proper flow of drilling fluid and protects the production casing. It also allows for the installation of anti-blowout devices, leak prevention devices, and liner pipes within the wellbore.

4. Production Casing: Remains in the wellbore long after drilling is completed, serving as the core channel for oil and gas production, protecting the wellbore from formation fluid erosion and providing space for downhole tools. Directly contacting the production fluid, it must possess high-pressure and corrosion resistance.

Oil Casing Specifications & Dimensions:

Outer Diameter: When produced, oil casing typically has an outer diameter of 114.3 mm to 508 mm.

Wall Thickness: Adjusted depending on strength and well conditions, typically between 6.45 mm and 16.1 mm.

Length: Single strands range from 8 to 14 meters, threaded together to form strings of hundreds to thousands of meters.

API specifies three casing lengths:

R-1: 4.88 to 7.62 meters;

R-2: 7.62 to 10.36 meters;

R-3: 10.36 meters and longer.

Material Properties:

Steel Grades: From low-strength H40 to ultra-high-strength Q125 (yield strength 276-1034 MPa);

Corrosion Resistance: Conventional carbon steel (J55), CO₂-resistant (13Cr), H₂S-resistant (C90).

OCTG Casing Steel Grades and Standards:

Oil casing is the lifeline of oil well operations. Due to varying geological conditions, downhole stresses are complex, with tensile, compressive, bending, and torsional stresses acting on the casing. This places high demands on the casing's quality. Damage to the casing for any reason can lead to reduced production or even the loss of the entire well.

Depending on the strength of the material, OCTG casing steel grades include H40, J55, K55, N80, L80, C90, T95, P110, Q125 and V150. The steel grade used varies depending on well conditions and depth. In corrosive environments, the casing must also be corrosion-resistant. In areas with complex geological conditions, it must also be resistant to collapse. Casing steel grades adhere to international standards such as API 5CT, with some imported products meeting ASTM standards.

Steel Grade

|

Yield Strength (MPa)

|

Features

|

Typical Applications

|

H40

|

276-552

|

Low cost, low strength

|

Shallow well casing

|

J55/K55

|

379-552

|

Economical, general

|

Shallow wells, water wells

|

N80

|

552-758

|

Medium to high strength, balanced cost performance

|

Medium to deep well technical casing

|

L80

|

552-758

|

Contains Cr (13%), corrosion resistant

|

Wells containing CO₂/H₂S

|

C90/T95

|

621-862

|

Anti-sulfur stress corrosion

|

High sulfur gas fields

|

P110

|

758-965

|

Ultra-high strength

|

Deep wells, shale gas fracturing sections

|

Q125

|

862-1034

|

Dedicated for ultra-deep wells

|

Ultra-deep wells, high temperature and high pressure wells

|

Special Steel Grades:

13Cr/Super 13Cr: For sour gas fields, CO₂ corrosion resistance

Duplex steel (22Cr/25Cr): commonly used in deep sea and high salt environments, resistant to Cl⁻ corrosion.

Nickel-based alloy (Alloy 825): used in extreme working conditions, resistant to H₂S+CO₂+high temperature.

Casing Structure and Performance:

(1) Structural features Casing type:

Seamless steel pipe (mainstream) or straight seam ERW welded pipe (used in some shallow wells)

Threaded connection: API standard thread (STC/LTC) or special thread type, such as VAM, FOX.

Multi-layer casing combination: conduit → surface casing → technical casing → production casing

(2) Performance characteristics

1. High strength: excellent tensile strength, anti-extrusion, and internal pressure resistance, such as N80 and P110 steel grades.

2. Corrosion resistance: Some steel grades contain alloys such as Cr and Mo, resistant to H₂S/CO₂ corrosion (such as L80-13Cr).

3. Sealing: Special threads ensure high-pressure gas sealing.

4. Adaptability: can cope with extreme working conditions such as high temperature (≤350℃), high pressure (100+MPa).

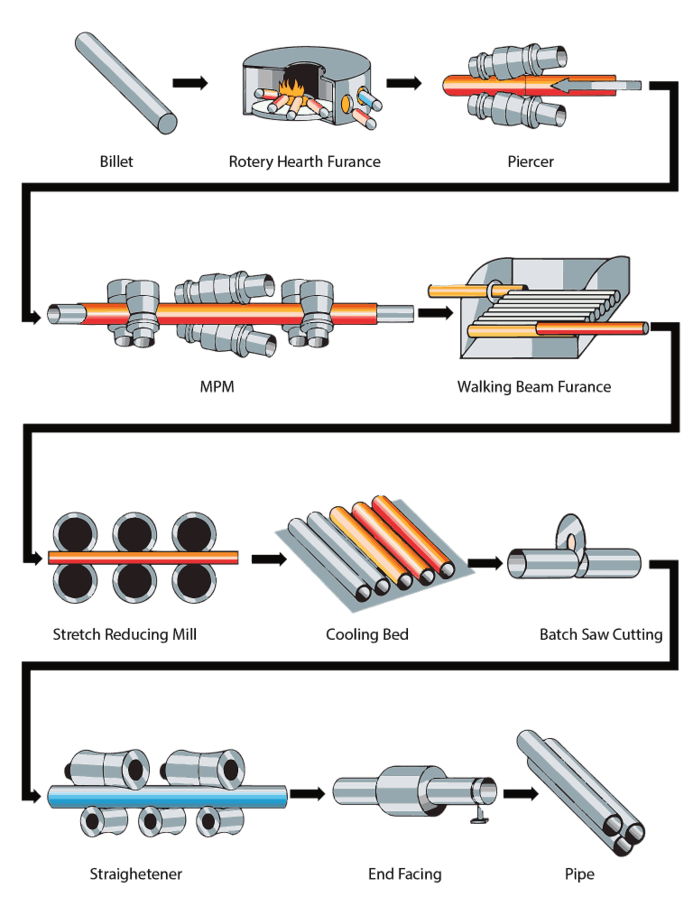

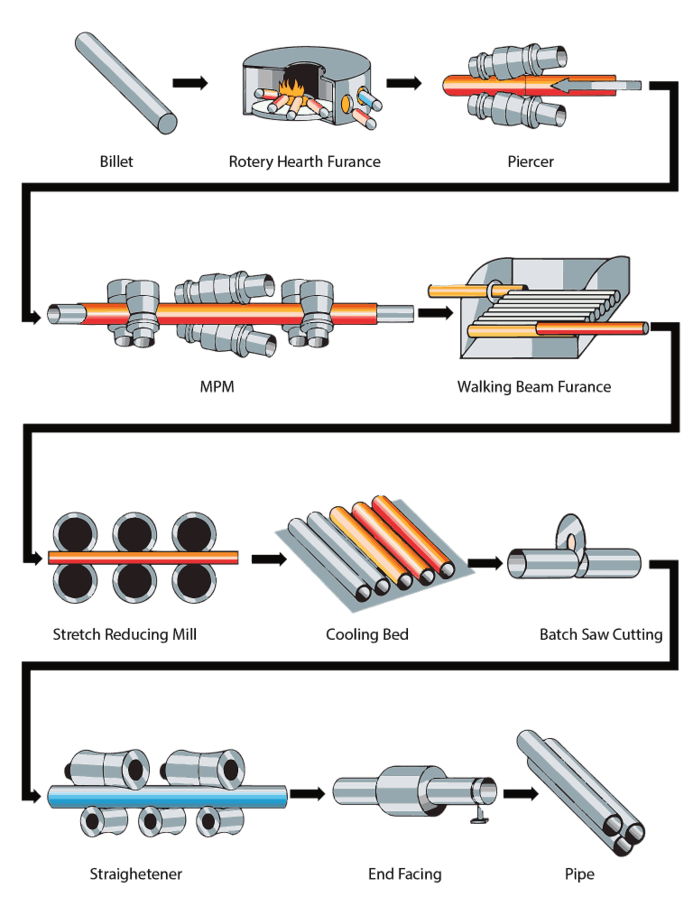

Casing Pipe Manufacturing Process:

Seamless Casing: no welds, strong pressure bearing capacity, high cost. Suitable for high-pressure wells and deep wells.

ERW Casing (straight seam welded pipe): high production efficiency, low cost, but the welds need to be strictly inspected. Suitable for shallow wells and low-pressure wells.

Steel ingot heating → hydraulic punching → reheating → extension → periodic rolling → reheating → sizing → cooling → straightening → pipe cutting → inspection

(1) Casing length is not fixed, ranging from 8-13m. However, casing not shorter than 6m can be provided, and the number shall not exceed 20%.

(2) There shall be no folds, hairline cracks, delamination, cracks, folds and scars on the inner and outer surfaces of the casing. These defects shall be completely removed, and the removal depth shall not exceed 12.5% of the nominal wall thickness.

(3) There shall be no defects such as folds, hairline cracks, delamination, cracks, folds and scars on the outer surface of the coupling.

(4) The thread surface of the casing and coupling should be smooth, and burrs, tears and other defects that are sufficient to interrupt the thread and affect the strength and tight connection are not allowed.

Application of Oil Casing Pipe:

Classification by well type:

1. Shallow well (<3000m): J55/K55 steel grade can be selected, and the common specifications are: 9-5/8", 7".

2. Medium-deep well (3000-5000m): N80/P110 steel grade can be selected, and the common specifications are: 7", 5-1/2".

3. Deep well/ultra-deep well (>5000m): Q125/V150 steel grade can be selected, common specifications are: 5-1/2", 4-1/2"

4. Shale gas horizontal well: P110+special buckle steel grade can be selected, common specifications are: thick wall 5-1/2".

Special environment application:

High sulfur gas field: L80, C90 sulfur-resistant steel grade

Deep-sea oil field drilling: Duplex steel + anti-corrosion coating

Geothermal well: 13Cr high temperature resistant casing

Core factors for casing selection:

Well depth: Shallow J55 for wells, Q125 for ultra-deep wells.

Pressure: High-pressure wells require thick-walled steel with P110 grade steel.

Corrosion: For sulfur-containing environments, choose C90/T95 sulfur-resistant steel.

Cost: ERW welded pipe is 30%-50% cheaper than seamless pipe.

Corrosion Prevention Measures for Oil Casing:

1. Ensure water quality meets standards and implement strict water quality testing and management. Implement separate injection of clean and dirty water, strengthen cleaning of main water pipelines, ensure water quality meets standards within stations and well bottoms, and reduce the introduction of corrosion sources into the annular space.

2. For newly commissioned injection wells, implement a strategy of adding An annular protection fluid with a sterilizing effect should be used, and a system should be established for regular dosing.

3. Given that mechanical abrasion accelerates corrosion of oil casing, it is recommended to add a rubber ring to the tubing coupling or a centralizer to areas of severe well deviation to prevent the tubing from scratching the casing or contacting the casing on one side during operations and water injection.

4. To address severe bacterial corrosion under scale and the slow growth and killing of SRB at high temperatures, 100°C hot water or steam can be regularly injected into the annulus to kill SRB under scale.

5. During water injection, Until internal corrosion in well casing is effectively controlled, the widespread use of cathodic protection and coated casing is not recommended.

Conclusion:

Oil casing is the "skeleton" of oil and gas wells. Its steel grade, size, and material must be selected based on a comprehensive consideration of well depth, pressure, and the corrosive environment. From low-cost J55 to ultra-strong Q125, from conventional carbon steel to corrosion-resistant alloys, different steel grades meet diverse needs, while specialized materials (such as 13Cr and duplex steel) are suitable for extreme operating conditions. In the future, high-performance, intelligent, and environmentally friendly casing will be the technological direction of development.

Read more: OCTG Casing Pipe Size Chart or Casing Pipe VS. Drill Pipe

In the oil production process, casing can be categorized by usage as: Conductor, Surface Casing, Intermediate Casing, and Production Casing.

In the oil production process, casing can be categorized by usage as: Conductor, Surface Casing, Intermediate Casing, and Production Casing.